MPD to PMD ™

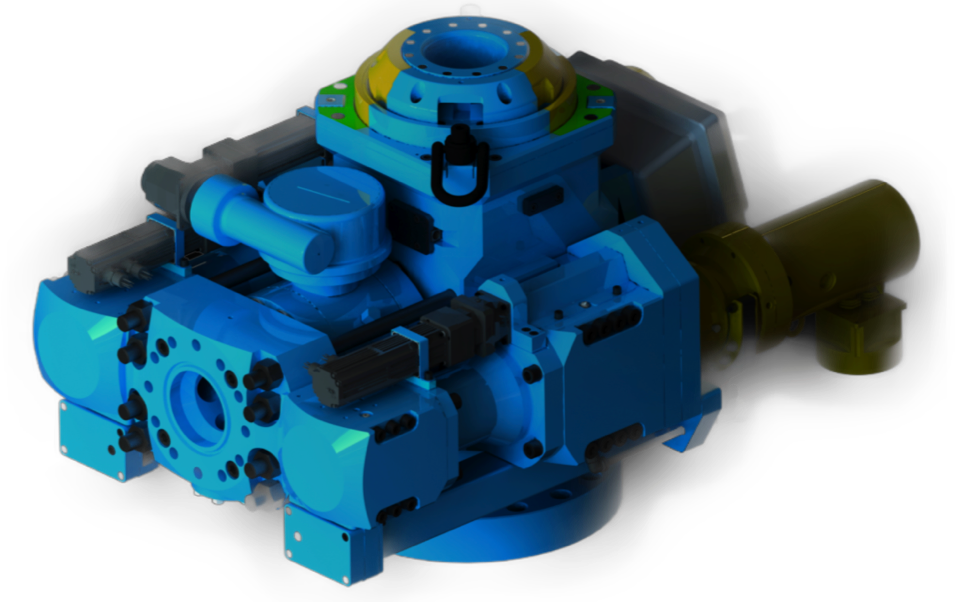

The future of Managed Pressure Drilling is here with Opla’s PMD™ (pressure management device). While

MPD (managed pressure drilling) is becoming a commonly used drilling practice, the techniques and

equipment haven’t changed in decades. The Opla team was formed with the common goal of bringing

disruptive technology to the drilling industry. PMD™ was designed and engineered with automation,

digitalization, performance drilling, and environmental factors in mind.

Speak with an

expert